|

|

Kaizen, the Japanese way for constant improvement

|

|

|

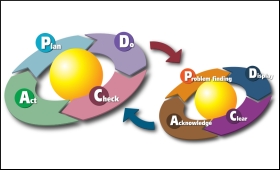

| The cycle of kaizen activity |

| Top Stories |

|

|

|

|

Writuparna Kakati | 24 Mar, 2009

What was the best thing Japan learned after World War II from the Americans? Sounds like a politically motivated question! Alright, just ignore it .... Let's we all start another way: What is the driving force behind the Japanese corporate culture? The Japanese people call this philosophy 'kaizen', one of the most popular buzzwords in today's business world.

Looking back

Stepping back into history a bit, the root of the kaizen as a management strategy can be traced back to World War II. After the end of the war, American occupation forces brought in American experts in who were familiar with the War Department's Training Within Industry (TWI) training programs to restore the nation. These TWI programs, in conjunction statistics-based methods taught by some American experts, later became the basis of the kaizen revolution in Japan that took place in the 1950s.

However, it was the Japanese who first saw the sense in the kaizen philosophy and the Western world came to know about the concept only when Masaaki Imai, a Japanese, reintroduced it in 1986 in his book, 'Kaizen: The Key to Japan's Competitive Success'. As a management tool, several Japanese businesses had implemented kaizen much earlier during the country's recovery after World War II. In 1950, Toyota, for instance, implemented this strategy leading to the development of Toyotaâs unique 'Toyota Production System' and the concept has since spread to businesses throughout the world.

Basic concept

So, what doest kaizen actually mean? In Japanese, kaizen means literally: change (kai) to become good (zen). It is actually a way of life philosophy suggesting that each and every aspect of our life should be constantly improved. It is a philosophical as well as a common sense approach with two primary elements: 'improvement to become better' and 'continuity'.

Features of kaizen

Today, the term 'kaizen' is used to refer to a process that gathers suggestions for improvements from employees. Sometimes the term is also used to suggest periodic meetings of employees where brainstorming improvement ideas are presented and immediately selected to make an improvement. Still some others think of kaizen as special events during which the presence of 'waste' is systematically detected and eliminated. All these kaizen methods, however, share some common features like:

- It means continuing improvement which can be small or large. Kaizen recognises that small improvements can make a big change.

- When applied to the workplace, kaizen means continuing improvement involving people working at all levels of an organization. From the CEO down, managers and workers - it is best if everyone is involved.

- The format for kaizen can be different; it can be individual, suggestion system, small group, or large group.

- When done correctly, kaizen cultivates the workplace, eliminates hard work and teaches people how to think in a new way and use new methods to recognize and eliminate 'waste'.

- Kaizen is a simple and relatively low cost team-based approach. Kaizen methods are intended to be repeated over a long time.

Implementing kaizen

So, how to implement a small kaizen in your workplace? Most companies use kaizen in one form or another be it called pull production, logistics improvements, just-in-time production, or lean manufacturing. But still, most of them fail to fully implement it due to lack of knowledge. Of course, there is more to implementing kaizen than one can include in a single page. However, the following steps are crucial in implementing kaizen at your workplace.

- First of all, it is important to realize that kaizen is less an action or a specific technique and more a mindset. Kaizen literally means 'changes for the better', and therefore, it is, first of all, a mindset and a commitment. The top management has to adopt this mindset, and make the commitment to ensure success of the kaizen methods at the workplace.

- Secondly, communication and training play an important role in implementing kaizen successfully at the workplace. To get kaizen started for the first time, small business can consider hiring outside experts who can observe the problems better than those close to the work at the workplace. In addition, it is very important to have an internal communication strategy that ensures uninterrupted flow of information at all levels from top to bottom.

- Thirdly, suggestions play a crucial role in kaizen. Employees must be encouraged to develop suggestions and managers must ensure that suggestions are acted on immediately - not in next month or next week, but today. Employees should be informed regularly about what happens with their suggestions and how they are implemented at the workplace.

- Fourthly, problems at the workplace should be seen as opportunities to improve and not as obstacles. In usual situations, nobody like to welcome problems but in the kaizen approach the focus remains on finding out, reporting, and fixing problems. An employee identifies a problem, develops an improvement idea which is reviewed by supervisors who, in turn, encourage immediate action and recognize the employee's accomplishment.

Concluding, kaizen is a simple and very cheap approach for continual development of a business. Compared to it, large scale improvement are more attractive but they are, at the same time, difficult to implement. For small and medium businesses, therefore, kaizen can be a better option to move forward through continual and incremental development activities such as cost reduction, improvement of delivery, slashing of cycle times and shift start-up times, quality improvement, effective implementation of supply chain management strategies, and many more.

|

|

|

| |

|

|

|

|

|

|

|

kaizen

George Corvin | Wed Apr 1 04:55:20 2009

Sure, to improve things is important and not many designs are perfect the first time. Unfortunately, they are getting worse. Proof: Things which used to last a lifetime are on the scrapheap after days or months. There are two problems: 1) that most designers are dotcom people with zero hands on experience, 2) that we should constantly produce new, not better, so that more rubbish can be sold. With the new billions of people arriving on earth, our planet will become desert. It is not kaizen what we need, but a reduced mass of of humanity, who buy needs, not whims, people who are able or taught to think and a world without immoral marketing, without the medical mafia and healthy living.

|

|

Re: kaizen

Ajay Gupta , MissionBiofuels India | Wed Apr 8 04:47:40 2009

It is a excellent technique for healthy improvements at all levels. But the Irony is we have failed to understand exactly what this word "kaizen" means in real terms. Again I would like to emphasize its a mindset, a commitment to have things better. In order to achieve its true potential we need to foresee its application beyond industry right from our basic way of life upto running the socio-economic affairs of a nation. Only then we will be able to unlock the true potential of this magical word.

|

|

|

|

|

|

|

|

|

| |

| Customs Exchange Rates |

| Currency |

Import |

Export |

US Dollar

|

84.35

|

82.60 |

UK Pound

|

106.35

|

102.90 |

Euro

|

92.50

|

89.35 |

| Japanese

Yen |

55.05 |

53.40 |

| As on 12 Oct, 2024 |

|

|

| Daily Poll |

|

|

| Do you think Indian businesses will be negatively affected by Trump's America First Policy? |

|

|

|

|

|

| Commented Stories |

|

|

|

|

|

|

| |

|